Case Study: Material Handling Equipment Dealership

- Equipment rental

- Fleet efficiency

- Fleet management

- Material handling

- Security and safety

How An Equipment Dealership Used Telematics to Enhance Customer Satisfaction and Loyalty

Discover how Atlas Toyota Material Handling used GemOne’s fleet management solution to grow their business with customers.

Telematics systems provide fleet managers with invaluable insights into their vehicles and drivers. Today, this technology has evolved into an indispensable asset for business owners and fleet managers alike, facilitating informed decision-making processes aimed at enhancing fleet efficiency and safety.

Atlas Toyota Material Handling is a material handling equipment dealership in the American Midwest that decided to incorporate GemOne telematics solutions into their dealership business. Through their collaboration with GemOne, Atlas has managed to level up their offering to customers..

In this post, we explore how telematics helped Atlas overcome the challenges they faced as a dealership business

“Telematics is here to stay. It’s not going away.”

— Giovanni G, Fleet Account Manager

Challenges for Dealerships Without Telematics

Before integrating GemOne’s Sapphire into their operations, Atlas faced several challenges. Giovanni and his team encountered difficulties in collating data, ensuring safety compliance, and tracking key operational hours efficiently.

Challenge 1: Data Collection

Collating data was labour-intensive and took huge amounts of time. The amount of valuable data that could be collected was limited. It was inefficient and frustrating. “We had to rely on work order history,” says Giovanni. “I’d physically have to go there and extract that data to pull out the necessary information.”

Challenge 2: Safety Compliance

Collating data was labour-intensive and took huge amounts of time. The amount of valuable data that could be collected was limited. It was inefficient and frustrating. “We had to rely on work order history,” says Giovanni. “I’d physically have to go there and extract that data to pull out the necessary information.”

Challenge 3: Tracking Machine Usage

Yet another challenge was the tracking of key hours of machine usage. “We still had technicians making house calls and walking to every single machine,” says Giovanni. “That’s 3 to 4 hours of the technicians’ time, walking across the site, driving to the site, and driving back.’’ In a time of labour shortage and rising fuel costs, technicians’ wasted hours and machine downtime were hurting business overheads.

“Without GemOne’s Sapphire, I feel like we would go back probably 50 years, and be a lot less productive.”

— Giovanni G., Fleet Account Manager

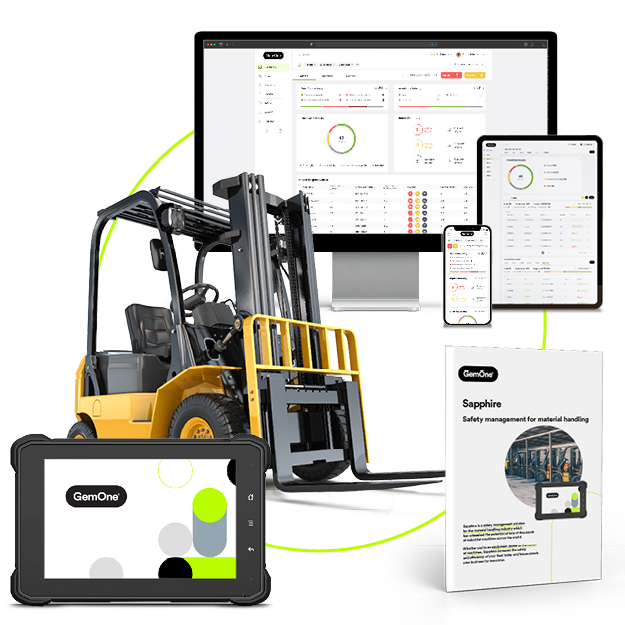

GemOne helped Atlas overcome these challenges with Sapphire, a telematics solution tailored to the unique needs of the material handling industry and designed to help businesses manage their forklift fleets more effectively.

“The biggest benefit of GemOne is the data that it provides. It’s very user-friendly, easy to read, and easily exported into an Excel spreadsheet to make a table for a customer,” says Giovanni.

Onboarding and installation at Atlas was quick and easy. Sapphire hardware is robust: IP67-certified, dust and water-resistant, and built to meet industrial demands. GemOne provided technical training for dealership sales and installation staff as well as comprehensive post sales account management support.

After adoption, Giovanni could see all the data from Atlas customer warehouses in an online cloud platform which meant Atlas could offer valuable and actionable business insights to their customers. “They can see what their utilisation is,” says Giovanni. “We can dive into the figures for them so they don’t have to. It helps them make a good decision on leasing or buying outright or even extending their lease.”

Business Benefits

Benefit 1 – More Effective Safety Compliance Support

With Sapphire, Atlas now helps its customers more easily manage safety compliance. Sapphire’s on-screen OSHA compliant safety checklists make pre- and post-start checks mandatory, with operator lockout if there’s a critical issue.

Not only does the safety checklist deliver insights into the behaviour of operators and the safety status of individual machines, but it tracks these user behaviours and safety issues in real time and makes the data available through a cloud platform on any device.

Benefit 2 – Safer Warehouses for Atlas Customers

Sapphire’s safety features such as Impact Reporting and Automatic Lock-Out mean Atlas can now better help their customers avoid the cost of human injury, equipment damage, and machine downtime.

With Impact Reporting, for example, Giovanni and Atlas customers are now able to record and analyse impacts on individual machines. The data provided about the level of those impacts in g-force can be combined with operator data and location insights to ascertain which areas in their warehouses are less safe and to establish which operators might require more targeted safety training.

Benefit 3 – Streamlined Operator Management Services

With Access Control functionality, Atlas now helps its customers put an end to the unapproved use of forklifts. In addition, Atlas uses Sapphire’s Session Reporting feature to end confusion amongst its customers about operator activity, monitoring the activity of operators on a daily basis to gain insights on efficiencies.

With Operator Licence and OSHA Training expiration tracking, Atlas customers can now ensure that their machine operators always comply with the appropriate OSHA training and licensing requirements.

Benefit 4 – Optimised Fleet Efficiency

With Utilisation Reporting, Atlas customers no longer have to guess which machines in their fleet are working the most.

“Right now I’m currently about to dive into an account that I’ve got to do a pretty large report for,” says Giovanni. “I’ll pull hours of data out of their GemOne site. It’s a national account so I can pull their 11 locations together and then extract the data. Simple.”

Benefit 5 – Improved Maintenance and Downtime Management

With Sapphire’s Utilisation Reporting feature, Giovanni sees real-time insights on the hours operated on each of Atlas customers’ machines to set service intervals proactively.

In this way, Giovanni helps his customers save on maintenance costs, reduce machine downtime, and optimise their operations. Better oversight on maintenance scheduling prolongs the lifespan of equipment and reduces costly repairs.

Atlas Toyota Material Handling remains committed to its partnership with GemOne, leveraging Sapphire’s capabilities to drive continuous improvement. Giovanni looks forward to integrating new features like camera systems and advanced analytics, ensuring sustained efficiency and customer satisfaction.

Improved Fleet Management with GemOne Sapphire

By implementing telematics technology, Atlas has improved safety standards, optimised fleet efficiency, and enhanced customer satisfaction.

You can download the full Atlas case study today for free to discover how GemOne telematics can improve fleet and safety management offerings for equipment dealerships in material handling and help them level up their customer service offering.

Top articles