Boosting Forklift Safety and Efficiency with New Load Sensor Technology

- Equipment rental

- Fleet efficiency

- Fleet management

- Material handling

- Security and safety

Forklifts are essential equipment in many industries, from manufacturing and warehousing to construction and logistics. Within these industries, operators need to be able to move heavy loads quickly and efficiently. But often, this comes with inherent risks.

One of the biggest challenges when operating a forklift is ensuring that the load does not exceed the forklift’s maximum weight capacity. This is where forklift load sensors can be incredibly valuable. When incorporated into fleet management solutions, load sensors offer a number of benefits that can help businesses improve safety, efficiency, and productivity.

Improving Safety

One of the most significant benefits of forklift load sensors is that they improve safety in the workplace.

Load sensors provide real-time feedback on whether the weight of the load exceeds safe limits.

Overloading a forklift can cause it to tip over, which can be dangerous for the operator and anyone else in the vicinity. By using load sensors, operators can avoid this risk and keep everyone in the warehouse safe.

Overloading a forklift doesn’t just put people at risk; it can also damage the items being moved.

When a load is too heavy, it can shift and become unstable during transport, causing items to fall off or become damaged.

By using load sensors, operators can ensure that the load does not exceed weight limits and reduce the risk of items moving in transit.

This can significantly reduce the risk of product damage, saving businesses money and helping them maintain a positive reputation with their customers.

Increased Efficiency

Another benefit of forklift load sensors is that they can help businesses increase efficiency.

Operators can make sure that they are transporting the maximum amount of goods possible without overloading the machine.

This can help reduce the number of trips needed to move a given amount of material, which can ultimately save time and increase productivity.

Incorporating forklift load sensors into your fleet management solution can also help improve maintenance practices.

By avoiding overloading, operators can minimise fuel and energy consumption over time and reduce wear and tear on their forklifts in the long-run.

Operating within safe limits ensures that the machines are not subjected to excessive stress, prolonging their lifespan and reducing maintenance costs.

In addition, the Hours Metering functionality of GemOne’s Sapphire’s fleet management system can be combined with data from load sensors to schedule maintenance activities based on actual equipment usage and condition, rather than arbitrary time-based intervals.

By identifying potential problems early on, maintenance can be performed promptly, reducing the risk of unexpected breakdowns and costly repairs.

Safety Compliance

Compliance with regulations and standards is of utmost importance in the material handling industry.

Weight restrictions, load limits, and occupational safety guidelines are in place to protect workers, equipment, and the overall integrity of operations. Failure to adhere to these regulations can lead to severe penalties, legal consequences, and reputational damage.

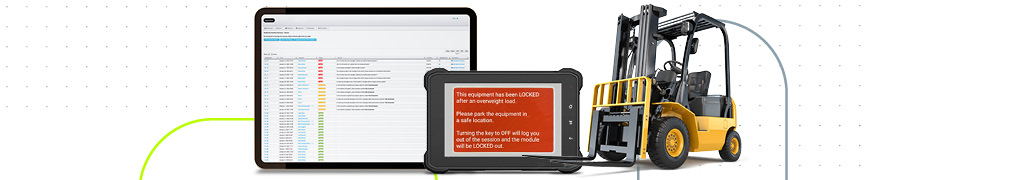

Fortunately, the load sensor function offered by our Sapphire fleet management solution provides a valuable tool for companies to meet these compliance requirements. The real-time alert system acts as a proactive safety measure by promptly notifying operators when load limits are exceeded. This feature empowers businesses to operate within the legal framework while maintaining a high level of safety and professionalism.

It enables operators to take immediate action, such as redistributing the load or reducing the weight, to avoid potential violations.

Maintaining compliance with regulations and standards also has broader benefits for businesses. It establishes a solid foundation of trust and reliability among customers, suppliers, and regulatory authorities.

Overall benefits

Incorporating forklift load sensors into your fleet management solutions can provide businesses with a number of benefits. By investing in this technology, businesses can ensure that their forklifts are operating at their maximum potential and ultimately save time and money while improving the safety of their workers.

If you’re considering installing forklift load sensors, be sure to research your options carefully and choose a solution that meets the unique needs of your business.

To learn more about the forklift sensor options that GemOne offers, grab a free brochure for our Sapphire fleet and safety management solution now.

Top articles