How Impact Reporting Works: Incident Notifications, Operator Lock-out, and Safer Driving Behaviour

- Equipment rental

- Fleet efficiency

- Fleet management

- Material handling

- Security and safety

In warehouse and material handling operations, safety is a top priority. Fleet management solutions have evolved to empower businesses to enhance safety practices and minimise costly incidents.

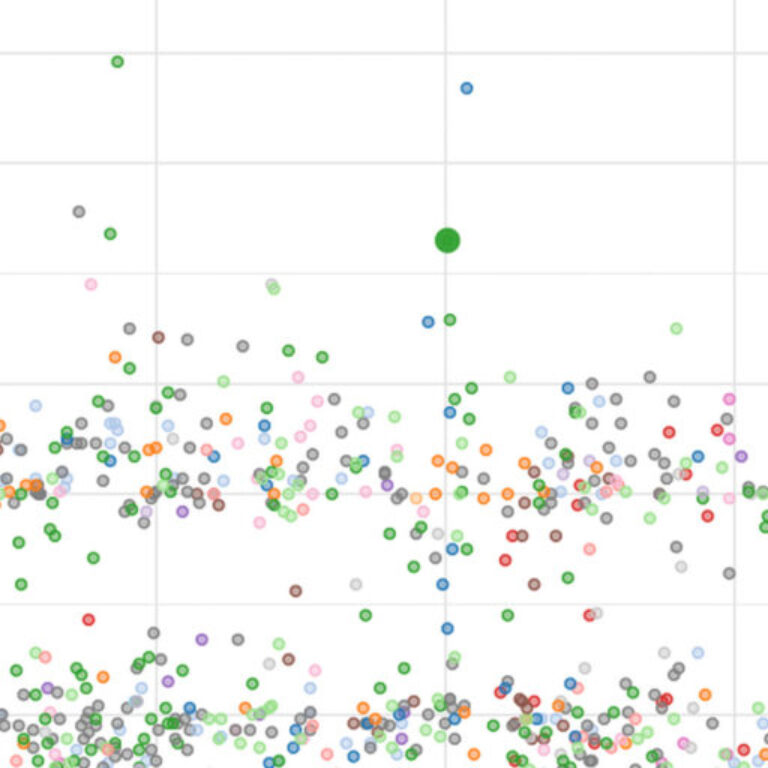

One notable feature of these new fleet management technologies is impact reporting, a feature which helps warehouse operations reduce equipment damage, prevent downtime, and foster a culture of safety through a series of real-time notifications which improve driving behaviour.

Another feature of impact reporting is automatic operator lock-out in the case of an incident. Businesses can establish their own lockout thresholds, preventing machinery from operating after an impact.

These thresholds can be tailored to specific needs and the work environment.

By setting impact level thresholds, businesses ensure that equipment undergoes thorough inspections and receives clearance for safe operation before resuming tasks.

This approach reduces the risk of further damage or accidents and emphasises the importance of equipment integrity in maintaining a safe working environment.

Improving Efficiency and Cost-effectiveness

Impact reporting not only enhances safety but it improves operational efficiency and cost-effectiveness.

By promptly addressing impacts and taking appropriate actions, businesses can minimise equipment downtime and reduce the need for expensive repairs or replacements.

Identifying high-risk areas and operators allows for targeted training and the implementation of preventive measures, resulting in a significant reduction in incidents and associated costs.

The impact reporting feature of GemOne’s Sapphire fleet and safety management solution enables businesses to optimise resources, streamline operations, and achieve better overall productivity.

Beyond real-time notifications and lockout thresholds, impact reporting can be enhanced with additional safety measures.

Businesses can add strobes and buzzer alarm beacons to promote safer driving behaviour, both within and outside the warehouse.

These visual and audible cues serve as reminders for operators to exercise caution, thus reducing the likelihood of incidents and creating a safer working environment.

Learn more about the transformative power of fleet management tools:

Are you interested in learning how a telematics tool like GemOne’s Sapphire solution can transform your business — download our free brochure here.

Top articles